Simple Tips About What Is The Purpose Of A Pull Box

What's the Deal with Pull Boxes? Unveiling Their Purpose

1. Why are these boxes even a thing?

Ever peeked into a commercial building or construction site and spotted a rather unassuming metal or plastic box attached to the wall, often labeled with a warning sticker? That, my friends, might just be a pull box. Now, before you start picturing boxes full of rope (although, that'd be kind of cool too), let's dive into what these things actually do. In essence, the purpose of a pull box, and "pull box" here is a noun, is to make pulling electrical wires through conduits a whole lot easier. Think of it like this: have you ever tried threading a needle with a super long piece of thread? Gets tangled, right? Same principle.

Electrical conduits are like the highways for electrical wiring. They protect the wires from damage and keep everything organized. But running wires through long or bent conduits can be a real pain. That's where our trusty pull box comes into play. It provides an access point along the conduit run, allowing electricians to pull the wires in shorter, more manageable sections. Without them, you'd need Herculean strength and a whole lot of patience. And nobody wants that!

Imagine trying to drag a garden hose through a series of tight turns without any breaks. You'd be fighting against friction and kinking the hose, right? That's what happens with electrical wires in conduits. The pull box is like a pit stop, reducing the amount of force needed and preventing damage to the wires. Plus, it allows electricians to inspect the wiring after it's pulled, ensuring everything is safe and sound. It's all about efficiency and safety in the electrical world.

So, next time you see one of these boxes, remember it's not just a random container hanging on the wall. It's a carefully placed access point that helps ensure your lights turn on, your appliances work, and your building doesn't suddenly decide to throw a fiery tantrum. Pull boxes are the unsung heroes of electrical installations! They are really important and make our electricians life's easier.

Electrical Pull Boxes Jefferson Concrete

Making Life Easier for Electricians

2. So, how exactly does a pull box work?

Okay, picture this: you have a long, winding pipe (the conduit) and you need to get a bunch of spaghetti (the wires) through it. If you try to push all the spaghetti in at once, it's going to clump up and get stuck. A pull box lets you break that long run into shorter, more manageable sections. Electricians use special tools like fish tape or pulling rope to guide the wires through the conduit. They feed the tape or rope through the conduit, attach it to the wires, and then pull the wires through.

The pull box provides a space to work and reduce the friction involved. When a conduit run is long or has multiple bends, the pulling force required to get the wires through increases dramatically. The pull box allows electricians to pull the wires to that point, then reposition themselves and continue pulling through the next section of the conduit. This significantly reduces the strain on the wires and the amount of effort needed by the electrician. It also minimizes the risk of damaging the wires during the pulling process.

Beyond making the initial installation easier, pull boxes also offer access for future maintenance and upgrades. Let's say a wire needs to be replaced or a new circuit added. Instead of having to run a new conduit all the way from the source, electricians can access the existing conduit through the pull box and run the new wire from there. This saves time, money, and a whole lot of headaches. It's like having a secret passage in your electrical system.

Furthermore, the size and placement of pull boxes are governed by electrical codes. These codes specify the maximum distance between pull boxes, the minimum size of the box based on the number and size of the conduits entering it, and other factors to ensure safety and accessibility. It's not just a matter of slapping a box on the wall; there's a whole science behind it! This attention to detail ensures that electrical systems are not only functional but also safe and maintainable over the long term. In essence, the "pull box" as a noun, is a game changer.

Premium Vector Push And Pull. Science Lesson. Force Motion. Kids

Safety First! The Role of Pull Boxes in Electrical Systems

3. Keeping things safe and sound.

Electrical safety is paramount, and pull boxes play a crucial role in maintaining it. By reducing the strain on wires during installation, they help prevent insulation damage, which can lead to short circuits, electrical fires, and other hazards. A damaged wire is a dangerous wire, and pull boxes help minimize the risk of damage during the installation process. It's like having a bodyguard for your electrical system!

In addition, properly installed pull boxes provide a secure enclosure for wire splices and connections. These connections are potential points of failure and can generate heat if not properly made. A pull box helps contain these connections, preventing them from coming into contact with other materials and reducing the risk of fire. It's like having a fire-resistant container for your electrical connections.

The use of pull boxes also facilitates the inspection and maintenance of electrical systems. Electricians can easily access the wires and connections within the box to check for damage, loose connections, or other problems. This allows for early detection of potential hazards and timely repairs, preventing more serious issues from developing. It's like having a regular checkup for your electrical system.

Moreover, many pull boxes are equipped with covers that provide a barrier against dust, moisture, and other contaminants. This helps protect the wires and connections from corrosion and other forms of degradation, extending the lifespan of the electrical system. It's like having a protective shield against the elements. Therefore pull boxes, where "pull boxes" is a noun, is really important.

America Pull Box Metal Electrical Square Lazada PH

More Than Just a Box

4. What are these boxes actually made of?

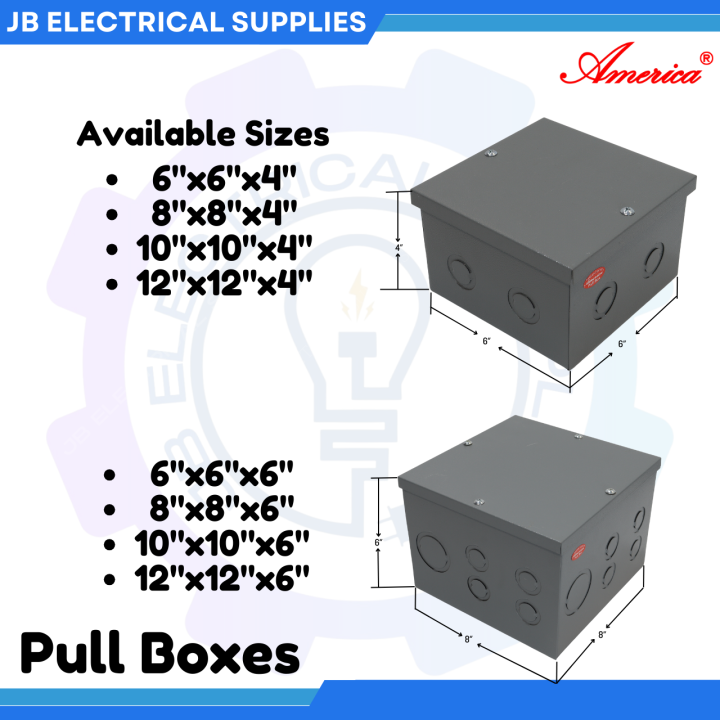

Pull boxes aren't one-size-fits-all. They come in various shapes, sizes, and materials, depending on the application. Metal pull boxes, typically made of steel or aluminum, are commonly used in industrial and commercial settings where durability and fire resistance are important. These boxes can withstand harsh environments and provide excellent protection for the electrical wiring inside. They are the workhorses of the pull box world.

Plastic pull boxes, usually made of PVC or fiberglass, are often used in residential and outdoor applications where corrosion resistance is a concern. These boxes are lightweight, easy to install, and resistant to moisture and chemicals. They are the adaptable chameleons of the pull box family. They are also suitable for direct burial applications.

The size of the pull box is determined by the number and size of the conduits entering it, as well as the number of wires being pulled through it. Electrical codes specify the minimum dimensions of pull boxes to ensure adequate space for wiring and connections. A box that is too small can make it difficult to pull wires and can increase the risk of damage. It's like trying to stuff too many clothes into a suitcase; something's gotta give!

In addition to standard pull boxes, there are also specialized types, such as junction boxes, which are used to connect multiple circuits together, and weatherproof boxes, which are designed to protect electrical connections from the elements. Each type of box is designed for a specific purpose and has its own set of requirements. They each play a specific role.

FAQ

5. All you need to know!

Let's tackle some frequently asked questions about pull boxes!

Q: What happens if I don't use a pull box when I should?

A: Skipping a pull box when one is needed can lead to damaged wires, increased pulling force, and potential safety hazards. It can also make future maintenance and repairs much more difficult. Basically, it's a shortcut that can cost you more in the long run.

Q: Can I install a pull box myself?

A: Electrical work can be dangerous, so it's always best to consult with a qualified electrician. They can ensure that the pull box is properly sized, installed, and grounded, and that all electrical codes are followed. Unless you're very knowledgeable and comfortable with electrical work, leave it to the pros!

Q: How do I know if a pull box is properly installed?

A: A properly installed pull box will be securely mounted, have a tight-fitting cover, and be grounded according to electrical codes. The wires inside should be neatly organized and free from damage. If you're unsure, have a qualified electrician inspect the installation.

Q: Are pull boxes only for commercial buildings?

A: Nope! While they're very common in commercial and industrial settings, pull boxes can also be used in residential applications, especially when running long or complex conduit runs. Basically, anywhere wires need to be protected and easily accessible.