Underrated Ideas Of Tips About Why Do VFD Fail

VFD Basics What It Is, How Works And Why You Need YouTube

Why Variable Frequency Drives Give Up the Ghost

1. Understanding the Culprits Behind VFD Failure

Variable Frequency Drives (VFDs) are workhorses in modern industry, controlling motor speed and saving energy. But like any piece of sophisticated tech, they're not immune to problems. Ever wondered why your VFD suddenly throws a tantrum and refuses to cooperate? Let's explore the common reasons behind VFD failures, so you can keep your motors humming and your operations running smoothly. Think of it as preventative maintenance — knowledge is power, and in this case, it can save you a bundle on repairs and downtime.

First off, let's acknowledge that VFDs aren't simple devices. They're packed with sensitive electronic components, from capacitors to IGBTs (Insulated Gate Bipolar Transistors), all working together under significant electrical stress. This complexity means there are plenty of potential failure points. We'll break down these causes into manageable chunks, so you can better understand what to look for and how to prevent issues before they happen. It's kinda like understanding why your car needs oil changes — essential knowledge for keeping things running!

Think of your VFD as a finely tuned race car. It needs the right conditions to perform optimally. Expose it to extreme heat, excessive vibration, or a poor power supply, and you're asking for trouble. We'll cover each of these environmental factors in detail, examining how they contribute to VFD malfunctions and what you can do to mitigate them. After all, a happy VFD is a productive VFD!

We'll also discuss the often-overlooked impact of improper installation and maintenance. Just like a house needs a solid foundation, a VFD needs proper installation and regular check-ups. Skipping these steps can lead to premature failure, leaving you scratching your head and wondering what went wrong. Believe me, a little preventative care goes a long way in extending the lifespan of your VFD.

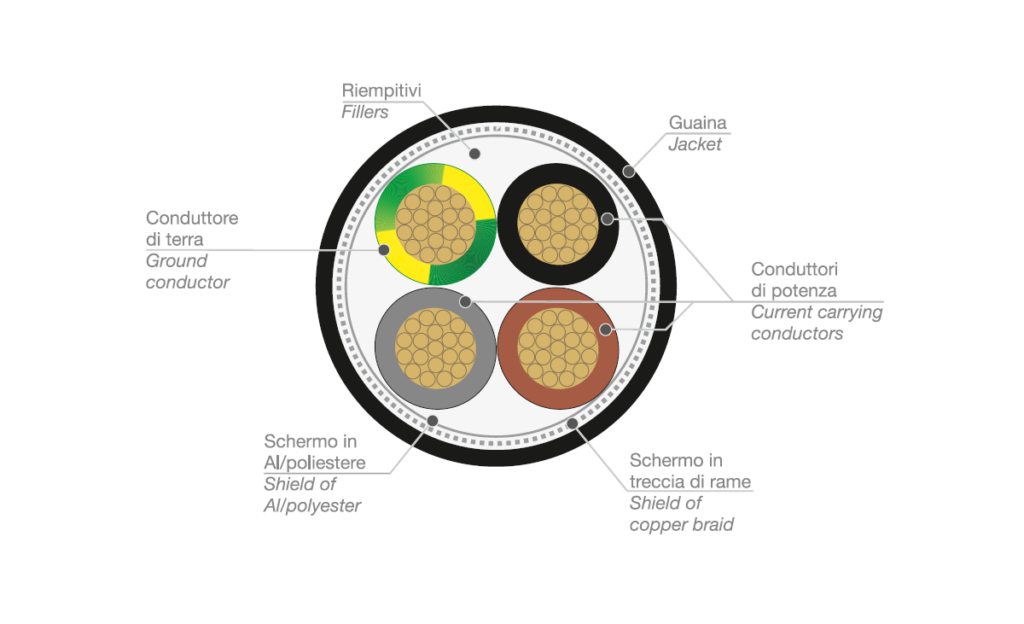

VFD Cables Tekima

Power Problems

2. The Role of Electrical Supply in VFD Lifespan

One of the biggest culprits behind VFD failure is the quality of the incoming power. Think of it as feeding your VFD a steady diet of junk food — eventually, it's going to break down. Voltage spikes, surges, and dips can wreak havoc on sensitive electronic components, particularly capacitors and diodes. These power fluctuations can be caused by various factors, including lightning strikes, utility switching, and even other equipment on the same electrical circuit.

Imagine your VFD is trying to juggle a bunch of oranges. If someone suddenly throws in a watermelon, the whole act is going to collapse. That watermelon is like a voltage surge, overwhelming the VFD's ability to maintain stable operation. To protect against these power problems, consider installing surge suppressors and line reactors. These devices act as filters, smoothing out the power supply and preventing damaging surges from reaching the VFD's delicate internals.

Harmonic distortion is another significant power quality issue. Harmonics are unwanted frequencies that can interfere with the VFD's operation and cause overheating. They're often generated by other non-linear loads on the same electrical system, such as computers, fluorescent lights, and even other VFDs. Addressing harmonic distortion may require the installation of harmonic filters or the use of VFDs with built-in harmonic mitigation features.

Furthermore, proper grounding is absolutely critical. A poor ground connection can lead to circulating currents and voltage imbalances, which can damage the VFD and even create safety hazards. Make sure your VFD is properly grounded according to the manufacturer's specifications and that the grounding system is regularly inspected and maintained. A solid grounding system is like a seatbelt for your electrical equipment — it provides essential protection in case of a fault.

Heat's On

3. Why Keeping Cool is Crucial for VFDs

Heat is the silent killer of electronic components, and VFDs are no exception. As VFDs operate, they generate heat due to the internal power losses of the electronic components. If this heat isn't properly dissipated, it can lead to component degradation and premature failure. Think of it like running a marathon in a fur coat — eventually, you're going to overheat.

One of the most common causes of overheating is inadequate ventilation. VFDs typically require a certain amount of airflow to keep their internal components within their operating temperature range. Make sure the VFD is installed in a well-ventilated area and that the cooling fans are functioning properly. Regularly check the fans for dust and debris, and clean them as needed. A clogged fan is like a blocked artery — it restricts airflow and can lead to serious problems.

Ambient temperature also plays a significant role. If the VFD is installed in an area with high ambient temperatures, it will have to work harder to dissipate heat. Consider using air conditioning or other cooling methods to keep the ambient temperature within the VFD's specified operating range. Remember, a cooler VFD is a happier VFD.

Overloading the VFD can also lead to overheating. If the VFD is forced to supply more current than it's designed for, it will generate excessive heat. Make sure the VFD is properly sized for the motor it's controlling and that the motor isn't being overloaded. Regularly monitor the VFD's current output to ensure it's within the acceptable range. Think of it as asking a small engine to power a large truck — it's going to strain and eventually break down.

The Vibration Blues

4. Impact of Vibration on VFD Performance

Vibration can be another insidious enemy of VFDs. Constant shaking and jarring can loosen connections, damage components, and even cause circuit boards to crack. While VFDs are designed to withstand some level of vibration, excessive vibration can significantly shorten their lifespan. It's like being a shaken soda can — eventually, something's going to explode.

One of the primary sources of vibration is the motor itself. If the motor is unbalanced or misaligned, it can generate significant vibration that is transmitted to the VFD. Ensure the motor is properly balanced and aligned to minimize vibration. Regular motor maintenance, including lubrication and bearing checks, can also help to reduce vibration levels. A smooth-running motor is a happy motor — and a happy VFD.

Vibration can also be caused by external sources, such as nearby machinery or even traffic. If the VFD is installed in an area with high levels of vibration, consider using vibration isolation mounts to dampen the effects. These mounts act as shock absorbers, preventing vibration from being transmitted to the VFD. Think of them as tiny pillows for your VFD, cushioning it from the harsh realities of the industrial world.

Regularly inspect the VFD and its surroundings for signs of excessive vibration. Look for loose connections, cracked components, or unusual noises. If you detect any problems, address them promptly to prevent further damage. Early detection and repair can save you a lot of headaches (and money) down the road. It's like catching a small leak in your roof before it turns into a major flood.

Neglect Never Pays

5. Preventive Measures for Long-Term VFD Health

Like any sophisticated piece of equipment, VFDs require regular maintenance to ensure optimal performance and longevity. Neglecting maintenance is like ignoring the warning lights on your car's dashboard — eventually, something's going to go wrong. A proactive maintenance program can help you identify and address potential problems before they lead to costly failures.

One of the most important maintenance tasks is to regularly inspect the VFD for dust and debris. Dust can accumulate on the internal components, insulating them and preventing them from dissipating heat properly. Use a vacuum cleaner or compressed air to remove dust from the VFD's enclosure and cooling fans. A clean VFD is a cool VFD.

Also, periodically check the VFD's connections to ensure they're tight and secure. Loose connections can cause arcing and overheating, which can damage the VFD. Use a torque wrench to tighten the connections to the manufacturer's specified torque. Think of it as tightening the lug nuts on your car's wheels — it's essential for safety and performance.

Another essential maintenance task is to monitor the VFD's performance. Keep an eye on the VFD's current, voltage, and temperature readings to identify any anomalies. If you notice anything unusual, investigate the cause and take corrective action. Early detection and intervention can prevent minor problems from escalating into major failures. It's like noticing a strange noise in your car's engine — it's a sign that something might be amiss.

How Do You Inspect A Rental VFD?

FAQ

6. Q

A: While there isn't a single "most common" cause, power quality issues (voltage spikes, surges, harmonics) and overheating are definitely high on the list. Proper installation, adequate cooling, and surge protection can prevent many of these issues.

7. Q

A: Often, VFDs can be repaired! It depends on the extent of the damage and the availability of replacement parts. Minor issues like capacitor replacement are usually straightforward. But if the main processor is fried, replacement might be the more practical route. It is always worth getting a qualified technician to assess the damage.

8. Q

A: It depends on the operating environment. For harsh environments (dusty, hot, or vibrating), you'll want to check things more frequently — perhaps monthly. For cleaner, more stable environments, quarterly checks might suffice. Always refer to the manufacturer's recommendations for specific maintenance intervals.