Perfect Tips About Is HMI A SCADA

Difference Between HMI And SCADA Anwar Kholidi Nasution

Unraveling the Mystery

1. Defining the Acronyms

Okay, let's cut to the chase. You've probably stumbled upon these techy terms: HMI and SCADA. They sound like something straight out of a sci-fi movie, right? But in reality, they're vital components in modern industrial operations. Think of factories, power plants, and even water treatment facilities — SCADA and HMI are often the unsung heroes behind the scenes.

So, what exactly are they? HMI stands for Human-Machine Interface. Simply put, it's the dashboard that operators use to interact with a machine or a system. Imagine the touchscreen on your phone or the control panel on an oven; those are HMIs in their own right. They provide a visual representation of what's happening and allow you to input commands.

SCADA, on the other hand, stands for Supervisory Control and Data Acquisition. This is the big picture. SCADA systems are used to control and monitor entire industrial processes. Think of it as the brain that oversees everything. SCADA systems gather data from various sensors and devices, analyze it, and then send instructions back to those devices to keep everything running smoothly. It's all about managing a complex operation from a central location.

Now, here's where it gets a little tricky. Are they the same thing? Short answer: No. But are they related? Absolutely! Let's delve deeper.

2. The Relationship Between HMI and SCADA

Think of HMI and SCADA as siblings. They work closely together, but they have distinct roles. The HMI is like the face of the SCADA system. It's the part that the operator directly interacts with. Without an HMI, a SCADA system would be pretty useless to a human operator, as it's how they can monitor the information collected, make critical changes, and keep processes running according to the design.

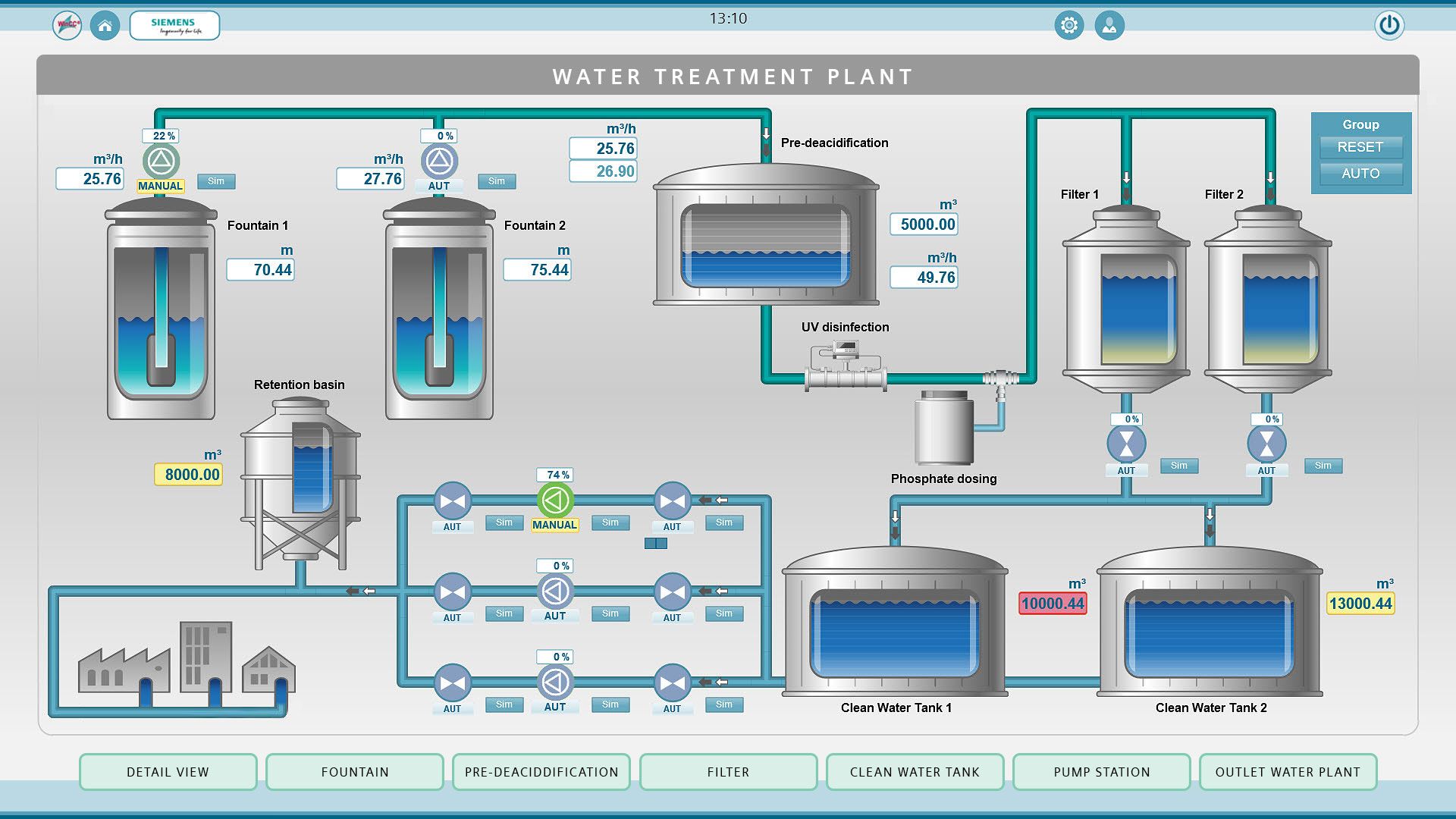

To illustrate, imagine a water treatment plant. The SCADA system is monitoring the water levels in various tanks, the flow rates through pipes, and the chemical levels in the water. The HMI is the screen that the plant operator uses to see all this information. The operator can use the HMI to adjust the pumps, open or close valves, and add chemicals to the water, all based on the data provided by the SCADA system and displayed on the HMI. So, the HMI is the window into the SCADA world.

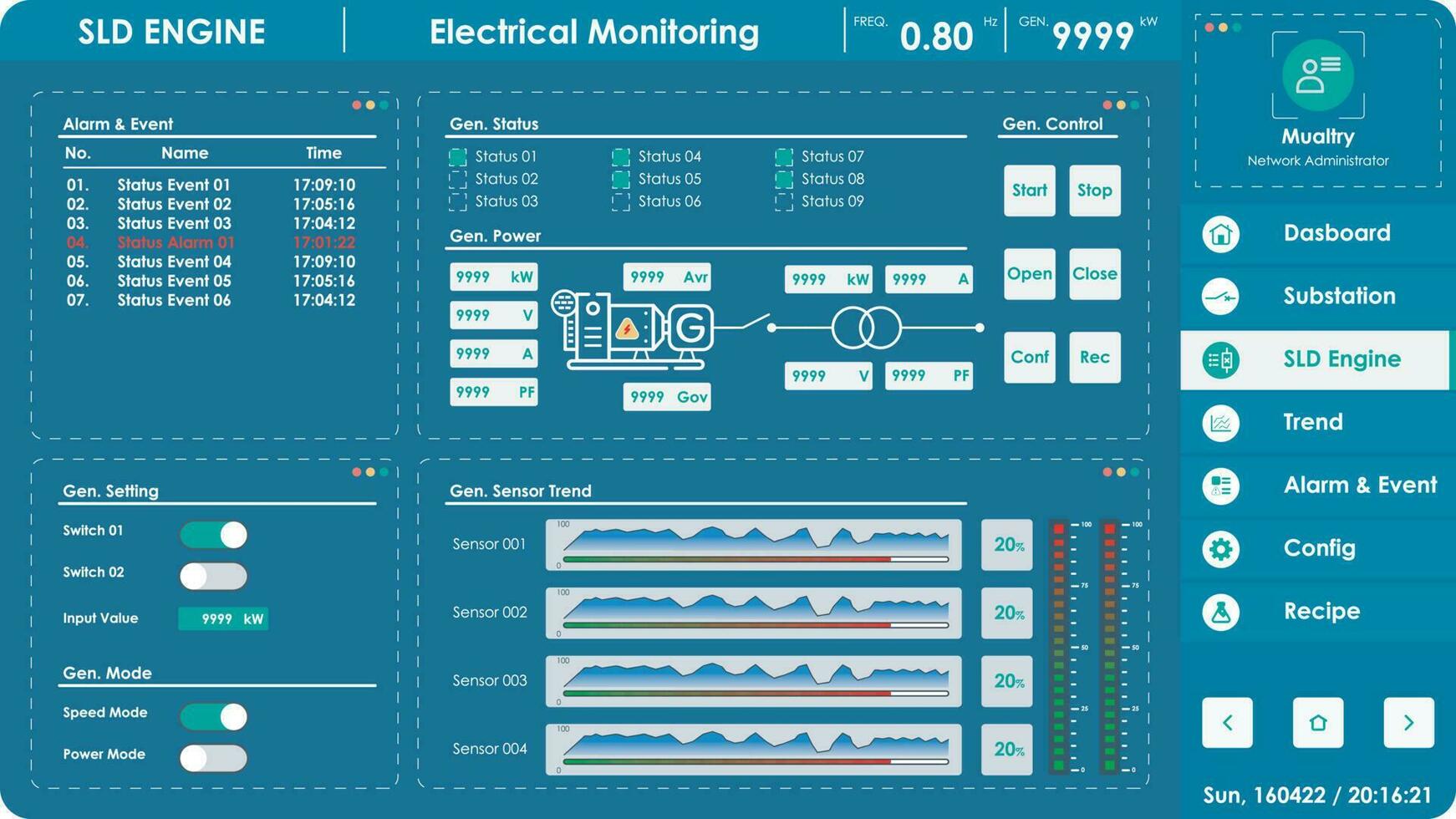

The SCADA system also handles the data logging, alarming, and reporting functions. It records all the data that's collected and generates alerts if something goes wrong. It also creates reports that can be used to analyze the performance of the system. The HMI simply displays this information in a user-friendly format. It acts more as a translator of complex data.

Essentially, you can think of the HMI as a component of the larger SCADA system. SCADA systems are much bigger and encompass a broad set of hardware and software.

3. Can an HMI Function Without SCADA? Yes, But...

Here's a curveball. Can an HMI exist without a SCADA system? Yes, it can. HMIs can be used to control individual machines or processes that aren't connected to a larger network. For example, a simple machine on a factory floor might have its own dedicated HMI for operators to manage its functions.

In these standalone applications, the HMI acts as a direct interface to the programmable logic controller (PLC) or other control devices. The PLC is the "brain" of the machine, and the HMI allows the operator to communicate with the PLC. But, without SCADA, we don't have a full system.

However, the limitations of using an HMI without a SCADA system are significant. You're confined to controlling and monitoring only that specific machine or process. You don't have the ability to see the big picture or coordinate operations across multiple devices or locations. This approach is useful for simpler tasks, but it lacks the supervisory control and data acquisition capabilities that SCADA provides.

Think of it like using a calculator versus using a spreadsheet program. A calculator (HMI) is great for simple calculations on single numbers or small sets. But its a real pain to calculate and track many, many data points over a long period of time. A spreadsheet (SCADA) allows you to organize, analyze, and manipulate large quantities of data more effectively, providing a much broader view of whats happening.

4. SCADA and HMI in Action

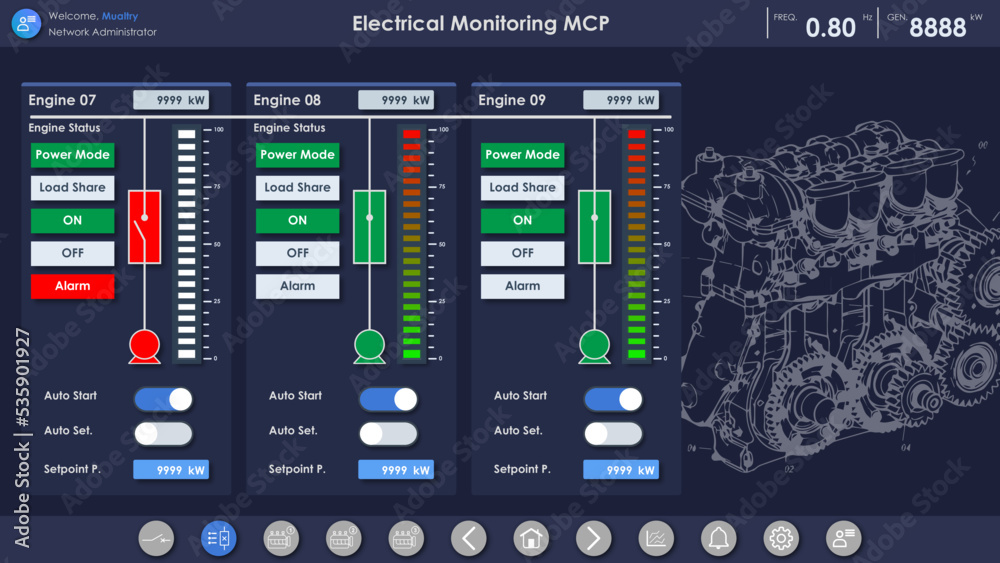

Let's bring this to life with some examples. In a power grid, a SCADA system monitors the voltage and current levels across the entire network. The HMIs are used by operators in the control room to view this information and make adjustments to keep the grid stable. If a power line goes down, the SCADA system will detect the fault and alert the operators through the HMI.

In a manufacturing plant, a SCADA system monitors the performance of various machines, such as robots, conveyors, and assembly lines. The HMIs are used by operators to monitor the production process and troubleshoot any problems. The SCADA system also collects data on production rates, downtime, and quality, which can be used to improve efficiency. An operator can see what the robot arm is doing and where its tolerances are, all through a touch screen (HMI).

Another common example is in oil and gas pipelines. SCADA systems monitor the pressure, flow rate, and temperature of the oil or gas being transported. HMIs are used by operators to control the pumps, valves, and compressors that keep the pipeline running smoothly. If a leak is detected, the SCADA system will automatically shut down the pipeline to prevent further damage.

The possibilities are seemingly endless. Almost every industrial process that requires monitoring, control, and data acquisition can benefit from the implementation of SCADA and HMI systems. It saves time, reduces costs, and improves efficiency.

5. In a Nutshell

To summarize, while an HMI is not a SCADA system in itself, it's a crucial component of one. It's the interface that makes the complex data and controls of a SCADA system accessible and usable to humans. HMI can exist independently, but it's far more powerful when integrated into a broader SCADA architecture. It displays data, allows for operational actions, and works with the SCADA's automation.

Think of it like a car. The SCADA system is the engine, transmission, and all the other mechanical and electrical components that make the car run. The HMI is the dashboard that displays the speedometer, fuel gauge, and other important information. You can't drive the car without the engine, but you also can't drive it safely and efficiently without the dashboard.

Ultimately, the choice between using an HMI alone or incorporating it into a SCADA system depends on the complexity of the application and the level of control and monitoring that's required. The more extensive the system, the more crucial that SCADA system becomes. The HMI acts as your personal window into that SCADA system.

So, the next time you hear someone mention HMI and SCADA, you'll know they're not interchangeable terms, but they're definitely close relatives in the world of industrial automation.

HMI SCADA UI Industrial Flat Design With Text Mualtry Administrator

FAQ

6. Frequently Asked Questions

Okay, let's tackle some common questions about HMI and SCADA to clear up any lingering doubts:

Q: Can I build a SCADA system without an HMI?

A: Technically, yes, you could build a SCADA system without a dedicated HMI. But would it be practical or useful? Probably not! The whole point of a SCADA system is to provide human operators with a way to monitor and control processes. Without an HMI, you'd have no way to visualize the data, issue commands, or respond to alarms. It would be like having a super-powerful computer that you can't see or interact with.

Q: Is a PLC the same thing as an HMI?

A: No, a PLC (Programmable Logic Controller) is not the same as an HMI. A PLC is the "brain" of a machine or process. It's a small computer that executes instructions to control the machine. An HMI, as we've discussed, is the interface that allows humans to interact with the PLC. The PLC makes the decisions; the HMI is how humans see what's happening and provide input. They work hand-in-hand, but they are distinct components.

Q: What are the key benefits of using HMI with SCADA?

A: The benefits are numerous! You get real-time visibility into your operations, improved control and efficiency, faster response times to problems, better data analysis and reporting, and increased safety. By integrating HMI with SCADA, you can optimize your industrial processes, reduce costs, and make better decisions.